The ability to weld is essential in numerous fields, including building and auto repair. It involves joining materials, often metal, using heat and pressure. Weld clamps are the key to achieving precise and robust connections, which are vital for safety and quality. These clamps play a pivotal role in welding, ensuring the materials remain in place and preventing any shifts that could compromise the weld’s integrity.

Welding clamps, available in diverse shapes and sizes, cater to specific tasks. Some are designed for holding thin metal sheets, while others can handle heavier materials. The exemplary clamp can significantly simplify welding and enhance final results. Choosing the appropriate type based on the specific work is crucial, as using an unsuitable clamp can result in uneven welds or damage to the materials.

When buying welding clamps, it is essential to consider things like substance, dimensions, and mass. Some clamps are crafted from durable metals, while others are lightweight. The clamp’s reach and clamping force are also crucial considerations, as they directly impact its ability to hold materials together effectively. We’ve rigorously tested a variety of welding clamps to identify the best options that enhance the welding experience and deliver reliable results. Click here for further information on our site, Ice Age Tools.

Best Welding Clamps

Our selection of the best welding clamps prioritizes long-term viability, quality, and input from end users. We understand the importance of your experiences and have considered them to help you find the right project tools that meet your needs.

Amazon Basics Metal Face Clamp

These clamps are a solid choice for anyone looking to tackle woodworking or welding tasks effectively.

Pros

- Firm grip for reliable holding.

- Easy to adjust and use.

- Good value for the price.

Cons

- Heavier than expected for quick tasks.

- May smoke under intense heat.

- Limited jaw width compared to some higher-end models.

We recently tried the Amazon Basics Adjustable Metal Face Clamp while working on a woodworking project. Right away, we noticed how well these clamps held everything in place. The grip is firm, ensuring that our materials didn’t move around while we drilled and screwed them together. This stability is crucial when working on precise projects.

Adjusting the clamps is quick and straightforward, thanks to the thumb screw knobs. We appreciated that we could easily change the jaw capacity without fuss. The swivel pads were an excellent touch, too; they distributed the clamping force well and prevented any damage to the surfaces we were working with.

However, the clamps are heavier than we expected for quick clamping tasks. While this added weight makes them sturdy, it can be cumbersome when working on repetitive actions. Additionally, we’ve heard some users mention that these clamps can smoke if they get too hot during welding. While it didn’t happen to us, it’s something to remember. Overall, regarding price and performance, these clamps are a worthy addition to our toolkit.

Jorgensen Bar Clamps

These clamps are a solid choice for light-duty tasks, making them a handy addition to our toolkit.

Pros

- A robust clamping pressure of 450 pounds ensures a secure grip.

- Drop-forged steel gives the clamps durability while remaining lightweight.

- Swivel pads help to distribute pressure evenly on the workpiece.

Cons

- They might feel stiff at first, requiring some effort to move.

- It is not suitable for heavy-duty applications; it is best for lighter jobs.

- The dimensions can be smaller than expected, which limits some uses.

We recently used the Jorgensen Bar Clamps for a woodworking project, and they performed well. The firm clamping force gave us confidence while we worked, preventing slippage. The drop-forged steel frame feels sturdy and light, making handling easy, even during longer setups.

The clamps were sometimes a little stiff when we first started using them. It took some adjustments to get them to slide smoothly. They worked fine once we loosened them with oil, but this minor issue continued their effectiveness.

The Jorgensen clamps shine for lighter jobs. Thanks to the non-marring pads, they were perfect for holding pieces together without worrying about damage. However, consider more heavy-duty options if you plan to tackle larger projects. Overall, these clamps are great for more straightforward tasks and worth considering for anyone who needs reliable support.

Grasshopper Magnetic Welding Finger

The Grasshopper Magnetic Welding Finger is an excellent addition for anyone looking to improve their welding setup.

Pros

- The magnetic solid base holds securely.

- It is excellent for holding small parts at tricky angles.

- Adjustable spring-loaded arm for varied pressure.

Cons

- It may only fit some work surfaces well.

- Limited hold-down pressure for thicker parts.

- It’s pricey for occasional use.

Using the Grasshopper Magnetic Welding Finger made our welding tasks much more manageable. The solid magnetic base impressed us. It firmly secured small parts like nuts and bolts while we worked. This feature is a game changer, especially for tack welding at odd angles.

Another highlight is the adjustable spring-loaded arm. We found it easy to modify the hold-down pressure, which allows for precision with different sizes of materials. It gives us more control, which is crucial when working with delicate components.

On the downside, we noticed that the grip may need to be more sturdy on surfaces that aren’t magnetic. Given its limited pressure, it struggled with more significant parts, too. Despite these minor drawbacks, the Grasshopper remains a valuable tool in our welding kit. It’s worth considering for anyone who frequently handles small pieces.

MAX POWER Heavy Duty F Clamp

We recommend the MAXPOWER Heavy Duty F Clamp for those needing reliable and sturdy clamps for various welding projects.

Pros

- It offers a jaw opening of up to 12 inches, which is great for large pieces.

- Enhanced clamping pressure ensures a firm grip on materials.

- The durable design resists rust and wear, extending the lifespan of the clamps.

Cons

- Slight flex under extreme loads may occur.

- Some users report a softer rigidity at maximum length.

- It may not match the premium quality of more expensive brands.

We have had a positive experience using the MAXPOWER Heavy Duty F Clamp. Its 12-inch jaw opening and deep throat make it suitable for numerous applications and substantial welding jobs. The clamps hold materials securely, which is essential when working on projects that demand precision.

The construction feels solid, and the black oxide spindle is a helpful feature against rust. It held firm while we worked with wood and metal, giving us confidence in their strength. Swivel pads Centre on workpieces nicely, providing a stable grip during welding.

We appreciate the value offered by this pack of two clamps. They are a smart buy for anyone looking to enhance their workshop tools without breaking the bank. While they might be of a different quality than higher-end brands, they do the job well for our needs.

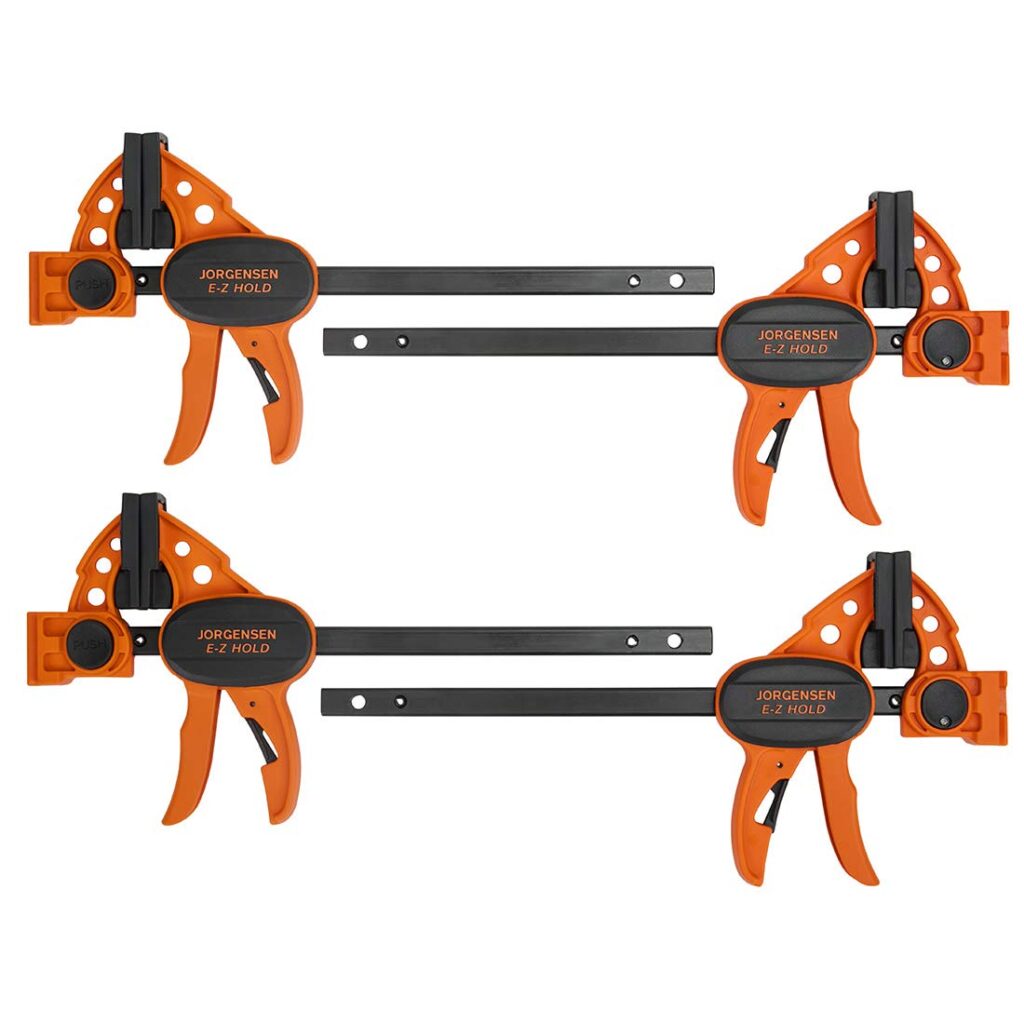

Jorgensen 6″ Spreader/Bar Clamp Set

These clamps are a solid choice for anyone looking for easy-to-use options for various clamping tasks.

Pros

- The quick-release lever allows for fast adjustments.

- Lightweight design makes them easy to handle.

- Versatile: can be used as clamps or spreaders.

Cons

- Limited to light-duty tasks, not for heavy applications.

- Some users may need to be more significant for larger projects.

- The plastic components may wear over time.

After trying the Jorgensen 6″ clamps, we were impressed with their comfort and ease of use. The contoured grip sits nicely in the hand, and the quick-release feature makes getting a solid grip effortless. We found that the lightweight aluminum construction keeps strength intact. These clamps hold securely without adding too much weight, which is excellent for long working sessions.

When we used them for various DIY projects, the flexibility to switch between clamping and spreading stood out. It’s handy to have a tool that can serve multiple purposes. However, we did notice that these clamps are lighter-duty. They may need help with larger projects or heavy materials, so keep that in mind if you’re working on something demanding.

We’ve found that the interlocking heads add an extra layer of usefulness. If we need to create a larger opening, we can easily combine two clamps, which is a neat feature for those bigger jobs. For anyone tackling hobby or craft projects, these Jorgensen clamps are a great addition to our toolkit.

Buying Guide

Selecting a suitable welding clamp is essential for achieving precise and robust welds. We can follow some key features to make the best choice.

Key Features To Consider

|

Feature |

Description |

|

Type |

Choose between C-clamps, toggle clamps, or others. Each type serves different purposes. |

|

Material |

Look for clamps made from durable materials like steel for strength and longevity. |

|

Size |

Ensure the clamp can handle the thickness of the materials we will work with. |

|

Grip |

A comfortable grip is essential for easy use during long tasks. |

Additional Factors

- Adjustability: Some clamps offer adjustable features to accommodate various sizes and shapes.

- Weight: Lighter clamps are easier to handle but should still be sturdy.

- Pricing: Determine how much you can spend and shop for the best deal within that range.

When choosing clamps, it’s crucial to assess our specific needs. With this information, we can select the best tool for each job. Try out a few different things until we find the one that works best for you and feels the most natural.

Selecting the best welding clamps is essential for ensuring solid and accurate welds. Materials, dimensions, and kinds are all critical considerations. A variety of clamps are helpful for various tasks.

When we pick our clamps, it’s good to priorities quality. Durable materials can withstand the heat and pressure of welding.

Using a suitable clamp improves both safety and efficiency. It also helps us achieve cleaner welds.

Investing in a variety of clamps gives us flexibility in our projects. We can tackle different tasks with ease. Always remember to check the clamp’s specifications before buying. That way, we know it will work for our purposes.

Frequently Asked Questions

We often get questions about choosing and using welding clamps. This section addresses essential considerations for various applications and types of materials.

What Characteristics Should I Look For In Welding Clamps For Heavy-Duty Applications?

When selecting clamps for heavy-duty work, consider the material they are composed of. No one can dispute the durability and sturdiness of steel clamps. To safely hold larger objects, ensure they have a firm grasp and a long reach.

How Do I Choose The Correct Welding Clamps For Woodworking Projects?

We should focus on clamps that provide a firm hold without damaging the wood for woodworking. Look for clamps with padded surfaces or those designed specifically for woodworking. Adjustable clamps can also be helpful to fit different sizes of wood.

Are Magnetic Welding Clamps Effective For All Types Of Metal Welding?

Magnetic clamps work well for certain types of metal, such as mild steel. They may hold less effectively on thicker or more porous metals like aluminum. Matching the clamp to the metal type is essential for the best results.

What Are The Advantages Of Different Types Of Welding Clamps In Various Applications?

Different types of clamps serve unique purposes. C-clamps are versatile and great for general use. T-slot clamps are helpful for precise setups, while magnetic clamps can hold pieces at specific angles. Choosing a suitable clamp helps improve efficiency and accuracy.

Can You Use The Same Clamps For Welding Steel As For Other Metals?

Even if it’s not usually a brilliant idea, you can use some clamps on steel and other metals. However, specific clamps might not provide a good hold on non-ferrous metals. They know which materials are compatible, guaranteeing an accurate hold and safety.

What Considerations Are Essential When Selecting Clamps For Grinding And Welding Tasks?

For grinding and welding, clamps need to withstand heat and vibrations. They should be sturdy enough to maintain a secure hold during these processes. We should also check for features like rust resistance to enhance durability.