Metalworking enthusiasts know sandpaper is essential to achieve a highly polished metal appearance. However, selecting the right sandpaper for metal can be daunting, especially for beginners. With numerous grit sizes, abrasive materials, and formats available, it can be challenging to determine which sandpaper is best for a particular metalworking project.

Empower yourself with a deep understanding of sandpaper properties and effective techniques. This knowledge is your key to feeling confident and capable of achieving the desired results as a metalworker. The right sandpaper grit size and abrasive material can effectively remove rust, scratches, and other imperfections from metal surfaces, preparing them for painting, polishing, or other finishing techniques. Whether you’re working with aluminum, steel, copper, or other metals, choosing the best sandpaper can make all the difference. Visit our site for more information on Ice Age Tools.

Key Takeaways

- Choosing the right sandpaper grit size and abrasive material is crucial for achieving a smooth and polished finish on metal surfaces.

- Different sandpaper formats and tools are available for various metalworking applications, from hand sanding to power sanding.

- Safety and maintenance are essential considerations when working with sandpaper to prevent injury and prolong the life of the sandpaper and tools.

Understanding Sandpaper And Its Uses

Discover the versatility of sandpaper, a tool for smoothing, polishing, and finishing various surfaces. Its backing material, whether cloth or paper, holds particles with abrasive properties, such as aluminum oxide or silicon carbide. With its multiple grits determining coarseness or fineness, sandpaper is not just a tool, but a canvas for your creativity in metalworking. Let it inspire you to create the perfect finish.

Types Of Sandpaper

Several types of sandpaper are available, each with unique properties and uses. The most common types of sandpaper are:

- Aluminum oxide sandpaper is the metalworking industry standard. It is durable, long-lasting, and suitable for various applications. It is available in multiple grits, ranging from coarse to fine.

- Silicon carbide sandpaper works wonders on tough metals like stainless steel and titanium. Sanding copper and bronze, two examples of non-ferrous metals, is also a typical usage.

Grit Explained

Grit, a term used to describe the size of the sandpaper’s abrasive granules, is a crucial factor in achieving the desired finish when sanding and polishing metal. The finer the abrasive particles, the higher the grit number. Coarse grit sandpapers, such as 40 or 60 grit, are used for heavy-duty sanding and quickly removing material. Fine-grit sandpapers, such as 400 or 600 grit, are used for polishing and finishing surfaces. Medium-grit sandpaper, with a grit size between coarse and fine, is an excellent all-purpose option for sanding and smoothing metal surfaces.

Sandpaper Materials

The backing material of sandpaper can be cloth or paper, each with its unique properties and uses. Cloth-backed sandpaper is more durable and tear-resistant than paper-backed sandpaper, making it ideal for heavy-duty sanding tasks. It is also less likely to clog with metal particles, prolonging its lifespan. On the other hand, paper-backed sandpaper is less expensive and more flexible than cloth-backed sandpaper. It is suitable for lighter sanding tasks and finishing work. However, it may wear out more quickly when used for heavy-duty tasks.

Understanding the different types of sandpaper, grits, and backing materials is crucial in choosing the right sandpaper for metalworking projects. Most metalworkers utilize sandpapers made of aluminum oxide or silicon carbide, with different grits used for other tasks. This knowledge will make you feel more informed and prepared for your metalworking projects.

Selecting The Right Sandpaper For Metal

Choosing the right sandpaper is crucial to achieving the desired finish when sanding and polishing metal. If you’re working with metal, this section will cover the basics of choosing the right sandpaper. By understanding and choosing the right sandpaper, you can feel more confident in your metalworking skills.

Assessing Metal Type

Assessing the type of metal is necessary, and You need to choose the sandpaper before you can start working on it. Softer metals like copper and brass require a different kind of sandpaper than harder metals like steel and iron. Fine-grit sandpaper is recommended for softer metals, while coarse-grit sandpaper is better suited for harder metals.

Grit Selection For Desired Finish

The grit size of sandpaper determines how coarse or fine the abrasive particles are. Coarse grit sandpaper has larger particles and removes rust, paint, and other surface imperfections. Fine-grit sandpaper has smaller particles and is better suited for achieving a smooth, polished finish. Medium-grit sandpaper is an excellent all-purpose option for sanding and smoothing metal surfaces.

When selecting the grit size, it is essential to consider the desired finish. Using a grit level of 320 or higher instead of 220 is ideal for rust removal, edge deburring, and finishing sanding between coats. If you are polishing metal, a much finer grit count, such as 1,200, is recommended.

Choosing The Right Sandpaper

Two main types of sandpaper are typically employed in the metalworking industry: silicon carbide and aluminum oxide. Regarding electric sanders and grinding discs, aluminum oxide sandpaper has a stellar reputation for long-term performance and durability. Brown aluminum oxide sandpapers are the most challenging and durable, making them ideal for heavy-duty sanding.

Sandpaper of silicon carbide works wonders on tough metals like stainless steel and titanium. Sanding copper and bronze, two examples of non-ferrous metals, is also a typical usage. Edge-core ceramic is another abrasive grain highly recommended for high-pressure grinding, as its micro-fracturing feature continuously exposes fresh abrasive grain during use. This versatile abrasive makes it an ideal choice for knife makers and blacksmiths.

When selecting sandpaper for metalwork, it is essential to assess the type of metalwork surface, choose a grit size corresponding to the desired finish, and choose the right sandpaper for the task.

Following these guidelines can achieve a smooth, polished finish on your metalwork project.

Sandpaper Formats And Tools

Sheets, Discs, And Belts

Sheets, discs, and belts are the three most common forms of sandpaper for sanding metal. Sheets are the most common type of sandpaper, available in various sizes. They are ideal for hand sanding and easily cut to fit the desired shape or size. Discs operate orbital sanders, while belts and belt sanders use them.

Sheets come in different grits, ranging from coarse to fine. The coarser grits remove rust and paint, while the finer grits polish and finish surfaces. You may also choose discs and belts in various grits for even more accessible and more efficient sanding with power tools.

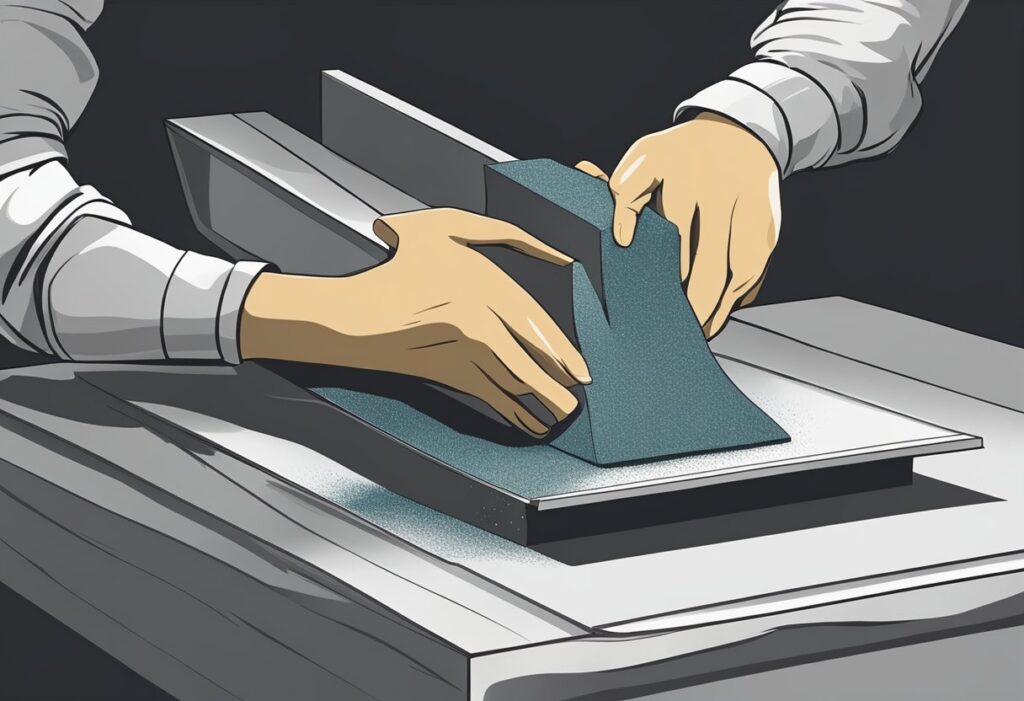

Hand Sanding Vs. Power Tools

Hand sanding is a traditional method of sanding metal using sandpaper wrapped around a sanding block or held in the hand. While it is simple and inexpensive, it can be time-consuming and tiring. However, Its shiny texture makes it ideal for use in metalworking processes.

Power tools like orbital sanders, belt sanders, and band sanders are ideal for larger and more complex jobs. They are faster and more efficient than hand sanding and can easily handle larger surfaces. Power tools are also available in different sizes and configurations to suit different jobs.

When choosing between hand sanding and power tools, consider the size and complexity of the job and the level of precision required. Hand sanding is the best option for delicate and small-scale tasks; power tools are your best bet for more extensive and more involved projects.

When choosing the proper sandpaper format and Getting a shiny, smooth finish on metal, you need a unique tool. Sheets, discs, and belts are the three main formats of sandpaper, each with its advantages and disadvantages. Hand sanding is a traditional method ideal for small and intricate jobs, while power tools are more effective when faced with larger and more complex tasks.

Sanding Techniques For Metal

A few techniques can achieve a smooth and even finish when sanding metal. In this section, we will explore some of the best sanding techniques for metal, including wet sanding vs. dry sanding, working with different metal shapes, and avoiding common sanding mistakes.

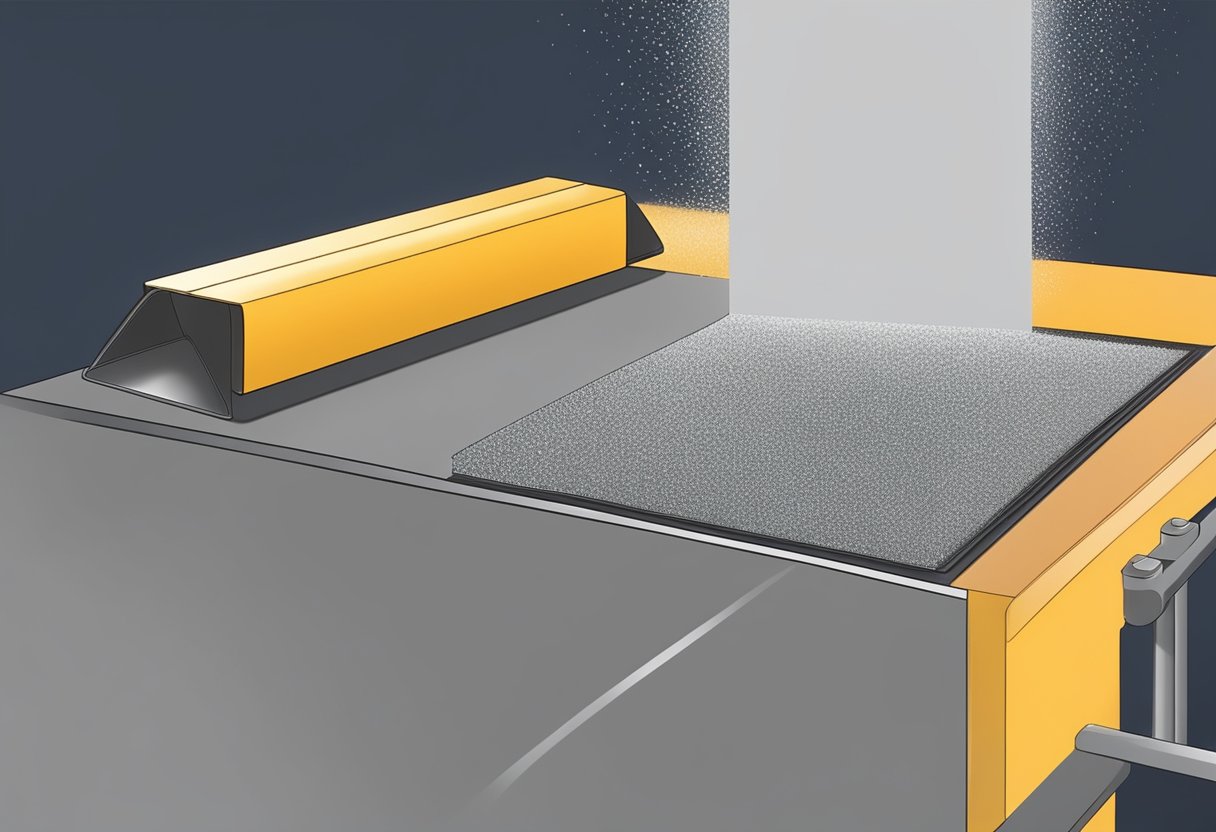

Wet Sanding Vs. Dry Sanding

Wet sanding and dry sanding are two popular techniques for sanding metal. Damp sanding uses water as a lubricant to reduce heat buildup and friction. This technique is ideal for preventing damage to the metal surface and achieving a smooth finish. Dry sanding also involves sanding metal without any lubricant or water. This technique is best for removing surface imperfections and scratches.

Working With Different Metal Shapes

Working with different metal shapes requires different sanding techniques. A sanding block or power tool can achieve an even finish for flat surfaces. Hand-sanding may be necessary for curved or irregular surfaces to reach all areas of the metal.

Avoiding Common Sanding Mistakes

One of the most common mistakes when sanding metal is using too much pressure, which can damage the surface. It’s important to apply even pressure and let the sandpaper do the work. Another mistake is using the wrong grit of sandpaper. To prepare the metal for priming and eliminate rust, use a coarser grit, and to polish it, use a finer grit.

Overall, using the proper sanding technique and avoiding common mistakes can help achieve a smooth and even finish when sanding metal.

Best Products: Sandpaper For Metal

When sanding metal, it is essential to use the correct type of sandpaper to achieve the desired results. Here are the best Amazon products for sanding metal:

Miady Assorted Grit Sandpaper

After trying the Miady sandpaper, we found it to be a versatile tool that meets our needs well. From finishing metal and wood to more delicate jobs, the assortment of grits (120–3000) covers the gamut from rough sanding to exquisite polishing. Regardless of the task at hand, its dependability shone through.

The waterproof silicon carbide construction, a durable and water-resistant material, impressed us. It worked nicely for wet sanding, often needed for projects involving rust removal or smoothing surfaces. We used it on several metal items, which held up well even after multiple uses.

One point to consider is that while this sandpaper works great, cloth-backed sandpaper lasts longer. For more demanding jobs, investing in those may be worthwhile. However, given the price and quality, this Miady set provides excellent value for general tasks.

Pros

- Wide range of grits for different tasks

- Waterproof material is adequate for wet sanding

- Easy to cut into custom sizes

Cons

- Cloth-backed options are more durable

- Some users prefer different grit options

- Not as long-lasting as higher-end brands

YXYL Sandpaper Set

We recently tried the YXYL sandpaper set and were impressed with its variety. With grits ranging from 120 to 5000, we used it for everything from rough sanding to polishing fine finishes. The silicon carbide material felt durable and worked well for dry and wet sanding.

Using the YXYL sandpaper was a breeze. Each sheet is clearly marked with its grit level, making it a simple task to select the right one for our needs. The 120 to 220-grit sheets were perfect for removing scratches, while the finer grits provided a smooth finish ideal for preparation before painting.

While the performance was solid, we did notice that the sandpaper could wear out faster than expected on rough surfaces. We had to be careful not to apply too much pressure to avoid ripping the sheets. Despite these minor issues, the overall quality and price make this a valuable kit for anyone looking to do metal work, automotive projects, or furniture finishing.

Pros

- Wide range of grits for different tasks.

- Good quality material that lasts well.

- Easy to cut to size for specific needs.

Cons

- It can wear out quickly on more challenging surfaces.

- A few sheets may rip if too much pressure is applied.

- The packaging could be better for storage.

HSYMQ 24PCS Sandpaper Variety Pack

The HSYMQ sandpaper variety pack has been a reliable partner for our DIY projects, making our tasks much more efficient. With 12 different grits, we can easily tackle any smoothing, polishing, or finishing work. Picking the correct grit for the job is straightforward, further enhancing our productivity.

When we opened the pack, we noticed that each sheet measures a convenient 9 x 3.6 inches. This size fits well in our hands, and the flexibility allows for excellent maneuverability. The grit markings on the back make it easy to choose what we need without second-guessing.

We experienced good results using the sandpaper on various surfaces. Whether wet or dry, the sheets held up well and did their job effectively. While they perform admirably, exerting too much pressure can cause bending. Overall, this pack has become a go-to for our sanding needs.

Pros

- Wide range of grits from 120 to 3000.

- Easy to cut into different sizes as needed.

- It works well for both wet and dry sanding.

Cons

- It can bend with heavy sanding pressure.

- Thinner sheets might wear out faster.

- Requires careful handling to prevent tearing.

3M Sandpaper 220 Grit

We recently used the 3M Aluminum Oxide Sandpaper for a metal project. The excellent grit worked wonders, leaving a smooth finish. It also held up well during use, showing minimal wear even after sanding a few larger surfaces. We appreciated how easily we could cut the sheets to fit our needs, whether for hand sanding or our power sander.

While this sandpaper performs exceptionally well, it may not be the best choice for heavy-duty tasks. If you need to remove a lot of material quickly, start with a coarser grit. The price is also slightly higher than other options, but the quality truly stands out.

In our experience, this sandpaper is versatile enough for various projects, from woodwork to automotive tasks. It sands nicely without clogging and leaves a clean surface ready for further treatment. Overall, the balance of quality and performance makes it a worthwhile investment for our toolbox.

Pros

- Great for multiple surfaces, including metal and wood.

- Excellent grit provides smooth finishes.

- Durable and can handle tough sanding jobs.

Cons

- Some might find the excellent grit less effective for heavy material removal.

- Not the cheapest option available.

- Requires careful handling to avoid tears.

PAXCOO Sandpaper Assortment

We recently used the PAXCOO sandpaper assortment for several projects around the house. The range of 42 different grits is impressive. There’s a sheet for every need, from coarse for heavy sanding to ultra-fine for finishing touches. It makes it easy to tackle various tasks without running out of options.

In our experience, the sandpaper did a great job when used dry. It held up well without tearing or falling apart. However, a couple of sheets struggled a bit during wet sanding. They didn’t hold up as well as expected, a minor disappointment.

Using the sandpaper by hand felt comfortable, and the 9-inch length made it easy to handle. We found it versatile enough for our different projects, whether refinishing furniture or smoothing out rough edges on metal. Overall, the PAXCOO assortment offers excellent value for anyone looking to complete various sanding tasks.

Pros

- Wide variety of grits for different tasks

- Durable and holds up well during use

- Suitable for both wet and dry sanding

Cons

- Some sheets may break down when wet

- Not ideal for heavy-duty sanding

- Manual cutting can cause slight size variations

Overall, these Amazon products offer excellent options for sanding metal. Whether you need versatile sandpaper for all stages of metal sanding or fine-grit sandpaper for a smooth finish, a product on this list will meet your needs.

Safety And Maintenance

Protective Gear

Protective gear is essential when working with metal and sandpaper to prevent injuries and exposure to harmful particles. Gloves should be worn to protect hands from cuts and abrasions. You should wear a mask or respirator to protect yourself from breathing in toxic particles like dust. Donning a pair of safety goggles protects your safety. Googles to shielding for Sandpaper and Tools.

Proper maintenance of sandpaper and tools is essential to ensure their longevity. After use, sandpaper should be cleaned and dried before storage. Tools should be greased and cleaned frequently to prevent rust. It is also essential to inspect tools before each use to ensure they are in good condition and not damaged.

When working with metal and sandpaper, To avoid harm and injuries, one must be mindful of the possible risks and take the necessary measures to protect themselves from dangerous particles. Wearing protective gear and properly maintaining tools and sandpaper can ensure a safe and efficient work environment.

Advanced Applications And Tips

Polishing And Finishing Techniques

Selecting the correct sandpaper grit is essential when polishing and finishing metal surfaces. Finer grits, such as 600-800, are ideal for polishing and finishing, while coarser grits, such as 80-120, are better suited for removing rust and paint.

Working through ever-finer grits is vital to attaining a smooth and polished finish. Start with coarse-grit sandpaper and work your way up to finer grits. As a result, the metal surface will be left soft and polished, free of any defects or scratches caused by the prior grit.

Another essential factor to consider when polishing metal is the type of compound used. Polishing compounds are available in various grits to remove minor scratches and imperfections, leaving the metal surface smooth and shiny.

Removing Rust And Paint

Removing rust and paint from metal surfaces can be challenging. Coarser-grit sandpapers, such as 80-120 grit, are ideal for this task. Use a light touch and work fully to avoid scratching the metal.

For more prominent rust spots or areas with heavy paint buildup, a wire brush or sandblasting may be necessary. After removing the rust or paint, thoroughly cleaning the metal surface is vital for removing debris or residue.

Achieving A Smooth And Polished Finish

Take your time and work your way through the sandpaper’s finer grits to get a smooth, polished finish on metal surfaces. Sand the metal surface gently and gradually using grits of progressively finer sandpaper, starting with coarse grit and moving up the grit scale.

Once the metal surface has been sanded to the right finish, It needs a good cleaning to remove any dust or residue. After cleaning, a polishing compound can improve the metal’s sheen and smoothness.

Achieving a smooth and polished finish on metal surfaces requires the correct sandpaper grit, a light touch, and working through progressively finer grits. Rust and paint removal also requires a coarser grit sandpaper and may require additional tools such as a wire brush or sandblasting. With the proper knowledge and equipment, polishing metal surfaces to a mirror shine is within anyone’s reach.

Comparing Sandpaper Brands And Prices

Evaluating Quality And Cost

Regarding sandpaper, quality, and cost are two important factors to consider. While higher-quality sandpaper costs more, it can also last longer, provide better results, and save time and money in the long run. On the other hand, cheaper SA papers may wear out quickly, require more frequent replacements, and result in a less smooth finish.

One way to evaluate sandpaper quality is to look at the grit size. Heavy sanding is best accomplished with coarser grits (40 or 60), whereas finishing and polishing are best achieved with finer grits (220 or 320). Assorted grit sandpaper packs can be a good option for those who need a variety of grits for different tasks.

Another essential factor is the abrasive material used in the paper towel. Because it is long-lasting and efficient, aluminum oxide sandpaper is a standard tool for polishing metal. Sandpaper made of silicon carbide is another choice for metal sanding, mainly when working with finer grits. Garnet sandpaper is a less common option that can be effective for sanding wood and metal. Ceramic sandpaper and zirconia alumina sandpaper are more expensive options known for their durability and long-lasting qualities.

Popular Sandpaper Brands

Many sandpaper brands are available, ranging from budget-friendly options to higher-end brands. Some popular brands include Black+Decker, 3M, Norton, and Red Label Abrasives.

Black+Decker offers a 2.0 amp electric 1/4 sheet orbit sander that can be used with various grits of sandpaper, making it a versatile tool for sanding metal. Aouker HS85180 hand sander is another option that is compatible with a variety of sandpapers.

The renowned company 3 M offers a variety of sandpaper products, including those specifically designed for sanding metal. Norton is another reputable company that provides sandpaper in various grits and sizes, including flat sheets ready to be cut into pieces of any size. They also provide emery cloth, a type of sandpaper made from Emery, a hard mineral known for its abrasive qualities.

When comparing sandpaper brands and prices, the quality and durability of the sandpaper, as well as the user’s specific needs and budget, must be considered.

Specialized Sandpapers And Their Uses

Ceramic Sandpaper For Heavy-Duty Tasks

Ceramic sandpaper is an abrasive material ideal for heavy-duty tasks such as metalworking. It is made from a blend of ceramic grains and other abrasive materials, making it more durable and long-lasting than other types of sandpaper. Ceramic sandpaper is also known for its ability to grind down hard materials quickly and efficiently.

Ceramic sandpaper is commonly used in metalworking applications because it can withstand high temperatures and pressure. It is also ideal for grinding and shaping hard metals such as steel and iron. Ceramic sandpaper is available in various grit sizes, making it suitable for rough and fine sanding.

Garnet Sandpaper For Woodworking

Garnet sandpaper is commonly used in woodworking because it leaves a smooth finish on wood surfaces. Garnet, a naturally occurring mineral, is gentle and slightly abrasive on wood surfaces. Because it does not become clogged effortlessly, garnet sandpaper is perfect for sanding extensive areas. Garnet sandpaper is also known for preventing clogging, making it ideal for sanding large areas.

Garnet sandpaper is available in various grit levels to accommodate coarse and fine sanding. This tool commonly sands wood surfaces before applying a finish, like paint or varnish.

Emery Cloth For Polishing Metals

Emery cloth is sandpaper that is ideal for polishing brass, copper, and aluminum. Emery, a mineral with a stellar reputation for smoothing and polishing metal surfaces, is one of several abrasive minerals used in its construction. Emery cloth is also available in various grit sizes, making it suitable for rough and fine polishing.

Emery cloth is frequently used in metalworking processes requiring a shiny result. It is also ideal for removing scratches and blemishes from metal surfaces. Emery cloth is available in sets, rolls, and belts, making it easy to polish various tasks.

Overall, specialised sandpapers such as ceramic sandpaper, garnet sandpaper, and emery cloth are ideal for specific tasks such as metalworking and woodworking. Users can attain a flawless, polished surface by selecting the appropriate sandpaper.

Frequently Asked Questions

What Type Of Sandpaper Is Most Effective For Removing Rust From Metal Surfaces?

Silicon carbide sandpaper is the most effective method for removing rust from metal surfaces. This type of sandpaper is known for its durability and ability to cut through rust and other rigid materials. For best results, use a grit of 320 or above rather than 220.

How Do I Select The Appropriate Grit Sandpaper To Prepare Metal For Paint?

Selecting the appropriate grit sandpaper for preparing metal for paint depends on the paint’s purpose. The first layer needs to be applied lightly and evenly. After the paint has dried, sand between applications using fine-grit sandpaper, often 400 grit or finer. A much finer grit count, such as 1,200, is recommended for a final coat.

Would You Recommend Aluminum Oxide Sandpaper For Metal Polishing?

Yes, aluminum oxide sandpaper is suitable for polishing metal. It works best on grinding discs and electric sanders and is particularly effective on harder metals like steel and iron. Brown aluminum oxide sandpaper is the most challenging and durable, making it ideal for polishing metal surfaces.

Is It Possible To Use 220 Grit Sandpaper Successfully On Metal?

Yes, 220-grit sandpaper can work well on metal, especially when polishing or smoothing. However, for initial metal removal, it is recommended to use a grit count higher than 220, preferably 320 or higher.

What Are The Differences Between Sandpapers For Metal And Wood?

The main difference between metal and wood sandpaper is the abrasive material used. Metal sandpapers typically use aluminum oxide or silicon carbide, which is more complex and durable than the abrasives used in wood sandpapers. Metal sandpapers also come in higher grit counts and are designed to cut through rigid materials like rust.

How Does 60-Grit Sandpaper Impact Metal Surfaces Compared To Finer Grits?

60-grit sandpaper is more abrasive than finer grits and is, therefore, more effective at removing material from metal surfaces. However, it can also leave scratches and grooves in the metal, which may require additional sanding with finer grits to smooth out. For the first round of metal removal, start with 60-grit sandpaper and work up to finer grits as you go.